Multi-Sigmaブログ

Multi-Sigmaアップデート情報や活用する際のヒントなどの記事を掲載しています。

第4回

TCIベンチャーアワード

優秀賞

第35回

中小企業優秀新技術・新製品賞

優秀賞

第3回

いばらきイノベーションアワード

優秀賞

エコテックグランプリ

2021

企業賞

深層学習を高度にチューニングすることで、少ないデータでも、過学習することなく高精度に予測が可能です。

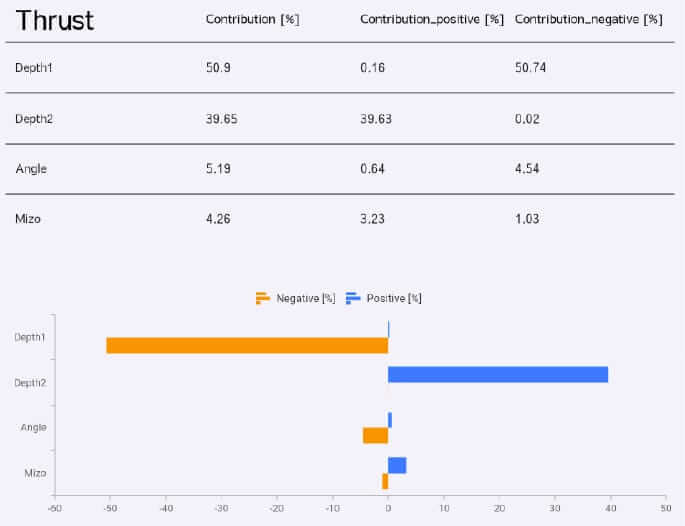

要因分析により、説明変数の寄与の大きさと、寄与の方向性について、定量的に分析することが可能で、ブラックボックスと言われるAIを説明可能にします。

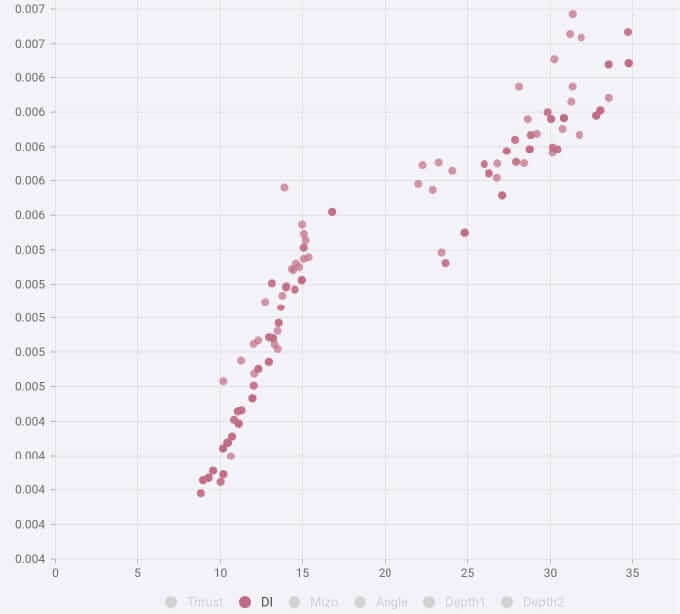

複数の目的を同時に満たす条件を、最適化のAIが自動で探索します。Pareto解の中から、お客様にとって最適なバランスの条件を抽出頂けます。

Google Cloud Platform 上で構築されているデータセキュアなSaaSアプリで、お客様にてハードウェアやソフトウェアをご準備いただく必要はありません。普段お使いのパソコンやタブレット端末のWebブラウザからAI 解析をしていただけます。

一般的な自動機械学習(AutoML)は、予測機能のみでアウトプットは一つのみですが、当アプリは、最大200個の説明変数から最大100個の目的変数を予測し、かつ100個の目的変数の条件を同時に満たす200個の説明変数を逆解析可能な世界で唯一*のアプリです。 * 2024/3時点

深層学習の2大技術といえるニューラルネットワークとベイズ最適化によるデータ解析の両方が利用できます。ある程度まとまったデータ(20個以上程度)で威力を発揮するニューラルネットワークと、最小のデータ数(3~5程度)からの逐次最適化で威力を発揮するベイズ最適化を組合せた解析が可能です。

深層学習を利用した予測と遺伝的アルゴリズムを利用した最適化を同時に1つのアプリで実行することが可能です。最適化のAIが予測のAIを使いながら、多目的な最適解を自動で探索することができます。

遺伝的アルゴリズムを利用し、多目的の最適化を行うことができます。目的変数の最大化・最小化・目標値設定と、説明変数の制約条件の設定が可能です。

予測モデル作成後、感度分析の技術により、どの説明変数がポジティブもしくはネガティブにどの程度効いているかを定量的に評価することができます。

AIエンジニアの必須スキルと言われているハイパーパラメータ(機械学習アルゴリズムの挙動を設定するパラメータ)のチューニングを自動で実施することができます。ボタン1つで過学習を抑制しつつ、高精度な予測が可能となっています。

従来の統計をベースにした実験計画法から、AIをベースにした実験計画法にすることで、多重共線性問題の解決、予測精度の向上、多目的な予測・最適化、実験計画の簡易化・無駄の排除が可能となります。

定性的なデータはダミー変数で、画像データは画像解析ツールで、パラメータ化して解析可能です。スペクトルデータは所定の幅でスペクトルを分割し、説明変数を作成することで、解析可能です。

予測精度を高めるための様々な前処理ツールを揃えるとともに、希少なデータや、偏りのあるデータに対しても、高精度に予測するための様々なツールが実装されています。

Multi-Sigmaアップデート情報や活用する際のヒントなどの記事を掲載しています。