Solution

Smart Agriculture

In agriculture, AI analysis has been gaining significant attention as a powerful tool for interpreting data obtained from experiments and field trials. However, there are numerous challenges in data analysis when it is difficult to comprehensively test all environmental conditions or crop growth patterns, or when dealing with rare phenomena such as infrequent pest outbreaks or extreme weather events. This article explores some of the challenges confronting the agricultural sector and introduces solutions utilizing

Multi-Sigma®.

1. Challenges in the Agricultural Sector

a. Complexity of Agricultural Data and Difficulties in Modeling

Modern agriculture is influenced by factors such as climate variability, and optimizing crop cultivation conditions requires numerous field trials and experiments under controlled environments. However, conducting agricultural trials often demands vast areas of land, long cultivation periods, and significant human and financial resources, making it extremely difficult to comprehensively test different crop varieties, fertilization conditions, and cultivation techniques. Moreover, due to spatial and temporal variability in weather and soil conditions, ensuring the consistency and reproducibility of trial results is also a major challenge. In addition, data obtained from drones and satellites through remote sensing and environmental sensors cannot be easily processed, and agricultural modeling that reflects diverse environmental factors requires a high level of expertise.

b. Unclear Underlying Mechanisms

In agricultural practice, numerous factors contribute to variations in yield and quality, with complex interrelations among daily operational management, weather conditions, pests and diseases, and soil conditions. Occurrences such as pest outbreaks or extreme weather events are infrequent and responses are often based on experience, making it difficult to statistically detect early signs of anomalies or analyze their causes. Achieving stable production of high-quality agricultural products while ensuring environmental sustainability and cost efficiency is a challenge that requires highly sophisticated decision-making and control.

c. Economic Losses Due to Insufficient Accuracy in Yield and Quality Predictions

In agricultural management, the ability to accurately predict crop yield and quality in advance has a significant impact on business decisions, ranging from sales planning and contract-based shipments to price negotiations and procurement of materials. A multitude of uncertain factors such as weather conditions, pest and disease outbreaks, fertilization and irrigation management, and variability in soil conditions, interact in complex ways to influence yield and quality, making accurate prediction challenging. As a result, there is a constant risk of economic loss, such as a decline in selling prices due to quality deterioration or unexpectedly poor harvests, or the loss of business opportunities from failing to meet contractual quantities. Furthermore, situations in which surplus harvests must be discarded also contribute to management instability. In this way, uncertainty in agricultural forecasting is a serious challenge that directly affects not only productivity but also economic sustainability.

2. What Multi-Sigma® Can Solve in the Agricultural Sector

a. Building High-Precision Prediction Models from Small Datasets

Conducting statistical analysis requires careful planning of experiments based on strict standards. Attempting to perform statistical analysis using only preexisting experimental data obtained without such planning makes it extremely difficult to achieve reliable predictions. In practice, even when experiments are conducted according to appropriately designed plans, real-world phenomena are often heavily influenced by factors such as nonlinearity, interactions, outliers, and data bias. In such cases, conventional statistical methods may fail to adequately capture this complexity, resulting in low prediction accuracy. This is particularly true for complex problems where multiple explanatory variables influence one another simultaneously, as higher-order interactions and nonlinear effects present significant analytical challenges. Typically, building a highly accurate AI model (machine learning model) requires a large volume of data. In contrast, Multi-Sigma® incorporates proprietary patented technology that enables the construction of high-precision prediction models even from small datasets, thereby overcoming traditional data volume limitations. This capability allows for the development of models that can accurately predict yield and quality from a limited number of experiments, significantly reducing the required time, labor, and financial resources. Multi-Sigma® includes a feature that proposes optimal experimental conditions for AI model development, delivering higher prediction accuracy even with a reduced number of experimental trials. Additionally, whereas conventional statistical models tend to limit the number of explanatory variables, AI models built with Multi-Sigma® can handle up to 200 different explanatory variables. This flexibility allows the system to identify and incorporate factors that might have been previously deemed unimportant but in fact play a critical role in prediction accuracy.

b. Contribution Analysis and Data Bias Correction

Multi-Sigma® is capable of handling up to 200 different explanatory variables. This makes it possible to comprehensively analyze factors that influence prediction targets such as yield and quality from a very broad range of candidates. Unlike conventional methods, which often limit analysis to a small set of variables, this capability allows attention to be given to factors that may have previously been overlooked. Furthermore, Multi-Sigma® does not simply classify the impact of each factor on yield or other targets as either an increase or a decrease. Instead, it quantitatively captures the relationship in both positive and negative directions. This enables accurate representation of complex interactions and nonlinear effects among variables, providing advanced support for causal interpretation and strategic planning by experts. In addition, Multi-Sigma® is equipped with a function to correct data bias for rare events with low occurrence frequency. By utilizing this feature, it is possible to address challenges that have traditionally been considered elusive, such as detecting early signs of anomalies and evaluating the impact of rare factors.

c. Leveraging AI to Improve Profitability

By using Multi-Sigma® to build high-precision prediction models from small datasets, it becomes possible to forecast future yields and quality levels in advance to a standard suitable for business applications. This enables agricultural management decisions to be optimized ahead of time, directly contributing to increased profitability. For example, if it is determined early on that yields will exceed initial expectations, securing appropriate buyers within that timeframe can reduce the risk of waste due to surplus inventory. Conversely, if a decline in quality is predicted, proactive coordination and information sharing with business partners can help maintain stable transactions without damaging trust. Moreover, knowing yield and quality in advance provides significant benefits for optimizing logistics and developing sales strategies. In addition, if the factors influencing yield and quality are identified, preventive measures can be implemented to mitigate the impact of such fluctuations, thereby minimizing risk. In this way, building high-precision AI models (machine learning models) can serve not only as a prediction tool but also as a core technology for improving overall business profitability in the agricultural sector.

Advantages of Multi-Sigma®

a. Deep learning with minimal data

Multi-Sigma® enables modeling and analysis from small experimental datasets, reducing experimental effort and shortening R&D cycles across various fields.

b. High-precision prediction

Offering high-accuracy predictive, factorial, and optimization capabilities, Multi-Sigma® allows for realistic and effective analysis based on experimental data.

c. Multi-objective optimization

Capable of exploring up to 200 inputs to satisfy 100 outputs, Multi-Sigma® finds optimal solutions for multiple competing goals simultaneously, aiding in new material development and improving manufacturing efficiency.

d. Explainable AI (xAI)

Multi-Sigma® includes a factorial analysis function that reveals which inputs affect which outputs, their extent, and whether the impact is positive or negative, enabling users to interpret results and understand internal mechanisms.

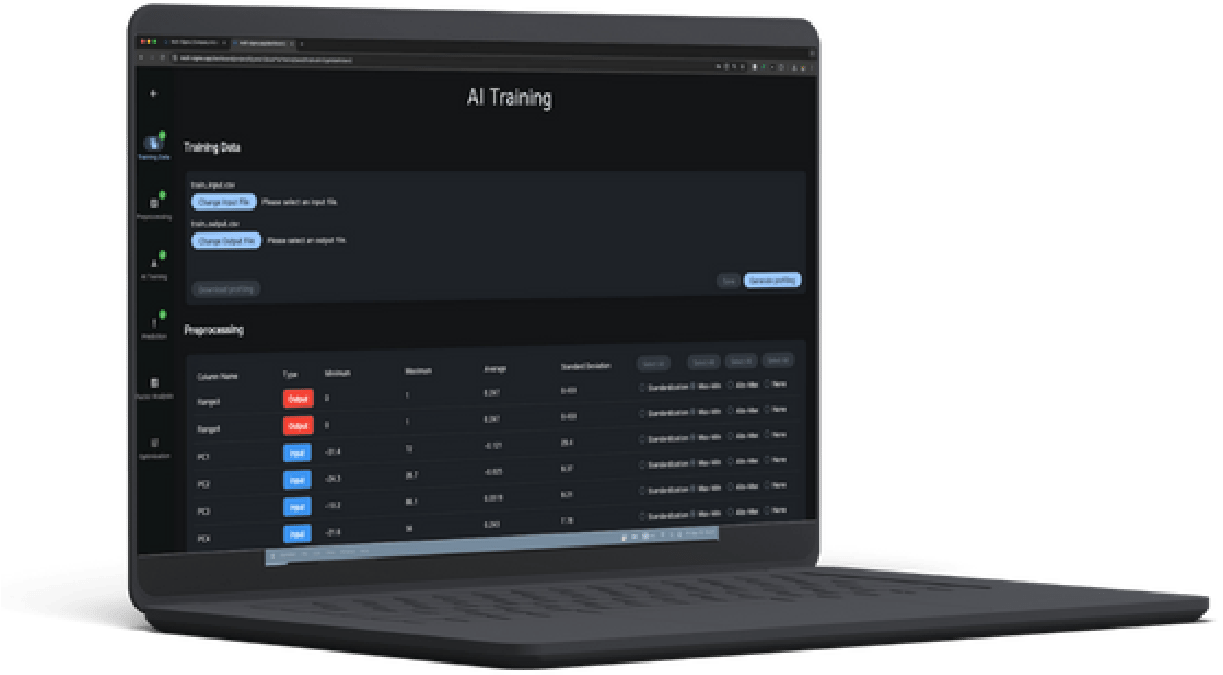

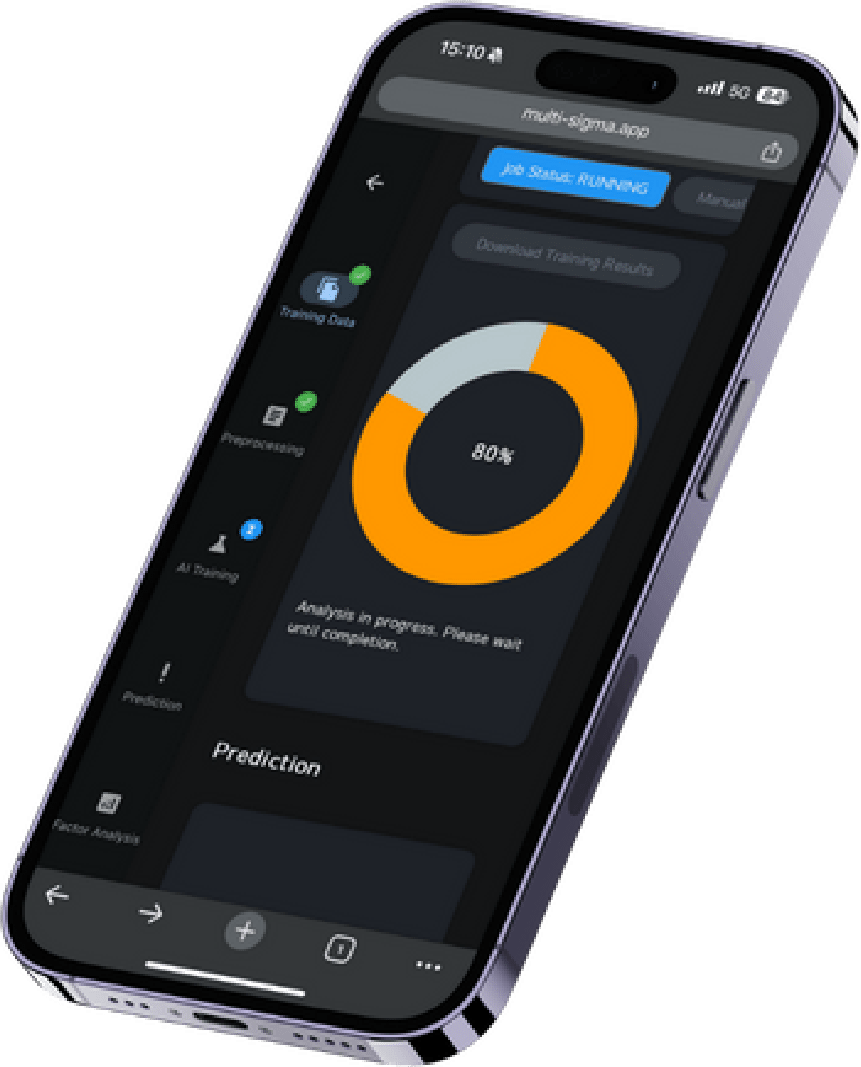

e. No-code and cloud-based

Requiring no programming skills, Multi-Sigma® provides an intuitive interface for data analysis with just a few clicks. As a cloud-based tool, it continuously updates with new features and bug fixes based on user feedback.

f. Chain analysis

By linking inputs and outputs across multiple processes, Multi-Sigma®’s chain analysis function chains multiple AI models for comprehensive analysis, enhancing AI performance and revealing process mechanisms.