Solution

Product Design

Global competition in manufacturing is intensifying, creating strong pressure to shorten development cycles in automotive and many other industries. At the same time, products are becoming more complex and must deliver higher performance, which adds further pressure on design teams. This article explains how Multi-Sigma® can help address these challenges in modern product-design work.

Challenges in Product Design

Increasing Product Complexity and Performance Requirements

Today’s products, from aircraft to automobiles, combine advanced software and computing with sophisticated hardware. Hardware and software must work closely together to meet strict targets for performance, quality, and safety, and designers must also follow regulatory and functional-safety rules. Model-based development (MBD) is one way to manage this complexity, but building detailed models and simulations still requires a great deal of time and effort. Improving efficiency is therefore essential.

Shorter Development Timelines and Rising Technical Demands

The move toward carbon neutrality and software-defined products is accelerating innovation in the automotive field and bringing new entrants into the market. Similar pressure exists in electronics and industrial equipment, where companies must react quickly to market and technology changes while cutting development time. Technical requirements continue to grow. Safety, performance, and electromagnetic compatibility (EMC) all need detailed analysis. Engineers must integrate many CAE tools, such as structural, fluid, and electromagnetic analysis, to meet these requirements efficiently.

Knowledge Transfer and Workforce Shortages

In developed countries, an aging population is shrinking the labor force. Within design teams, experienced senior engineers are retiring, necessitating urgent transfer of their knowledge to younger engineers. Efforts to speed development with CAE tools face new hurdles. Shorter schedules and more complex specifications require both the training of simulation-capable engineers and the securing of sufficient, scalable computing capacity.

Solving Design Challenges with Multi-Sigma®

Robust Optimization with Variation Consideration

Products must deliver stable performance across many usage environments and manufacturing conditions. This stability, called robustness, is hard to study with traditional methods. With Multi-Sigma®, AI learns the relationship between design parameters and performance indicators, enabling highly efficient robust design analysis. The platform also supports multi-objective robust optimization, allowing engineers to simultaneously optimize for quality, strength, cost, and more. This helps address design areas that were previously difficult to explore.

Optimizing the Product Design Lifecycle

Product development now involves many design layers, from concept and system design to component modeling, testing, and full-system evaluation. Each stage has its own experts, and simulation results guide the next step. Multi-Sigma® builds accurate surrogate models from limited CAE data, such as structural or fluid simulations. These models speed up robust studies and optimization, reducing engineering effort. AI chain analysis links several surrogate models for system-level optimization. Engineers can also export the models to control-system simulators and evaluate the whole product.

Secure and Scalable Model Sharing

Design teams often need to share models, but simulation files can contain confidential know-how. Surrogate models made with Multi-Sigma® stay explainable inside the platform, yet hide detailed logic after export, allowing safe sharing across departments and partner companies.

Key Benefits of Adopting Multi-Sigma®

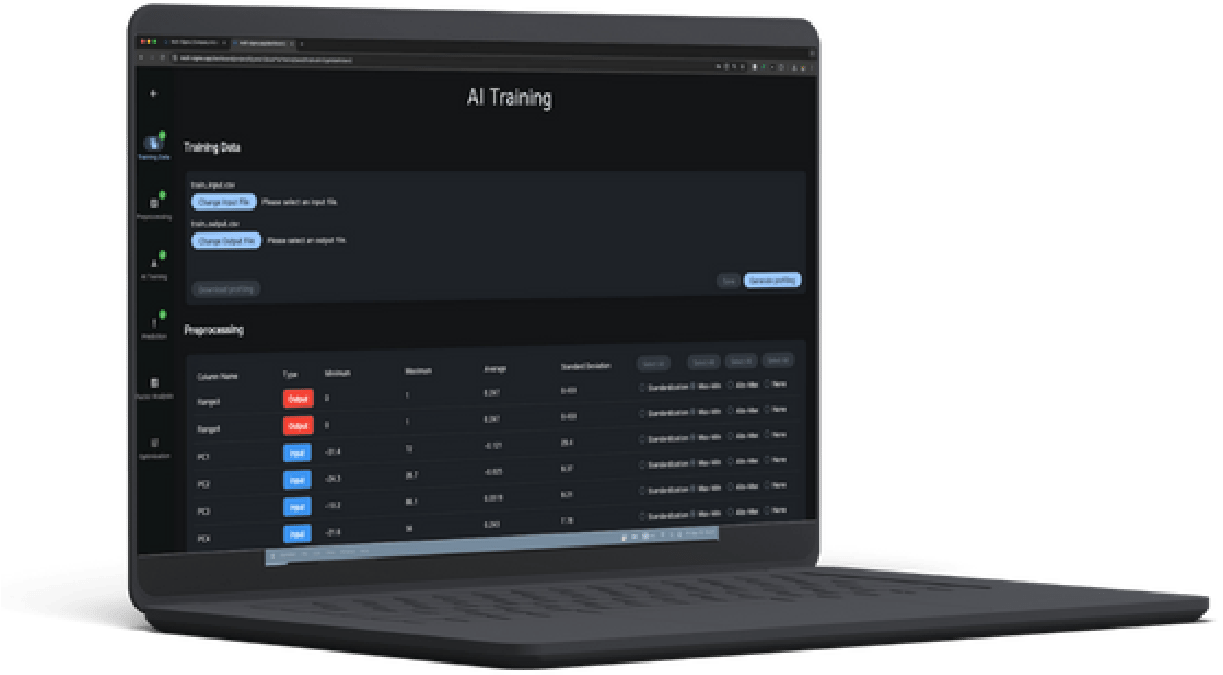

Build Accurate Models with Minimal Data

Multi-Sigma® builds high-accuracy AI surrogate models from a small number of experiments or CAE simulations. This reduces the preparation effort for AI adoption. It streamlines the design workflow and improves overall efficiency.

Run Multi-Objective Optimization and Robust Design Easily

The platform combines AI flexibility with cloud compute. Users can run multi-objective optimization and robust design studies through a simple user interface. Deep programming or optimization expertise is not required.

Explainable AI for Transparent Design Decisions

Product design changes require clear justification. Multi-Sigma® provides contribution analysis that quantifies how each design variable affects performance. Engineers can keep the design rationale explicit and increase confidence in AI-assisted results.

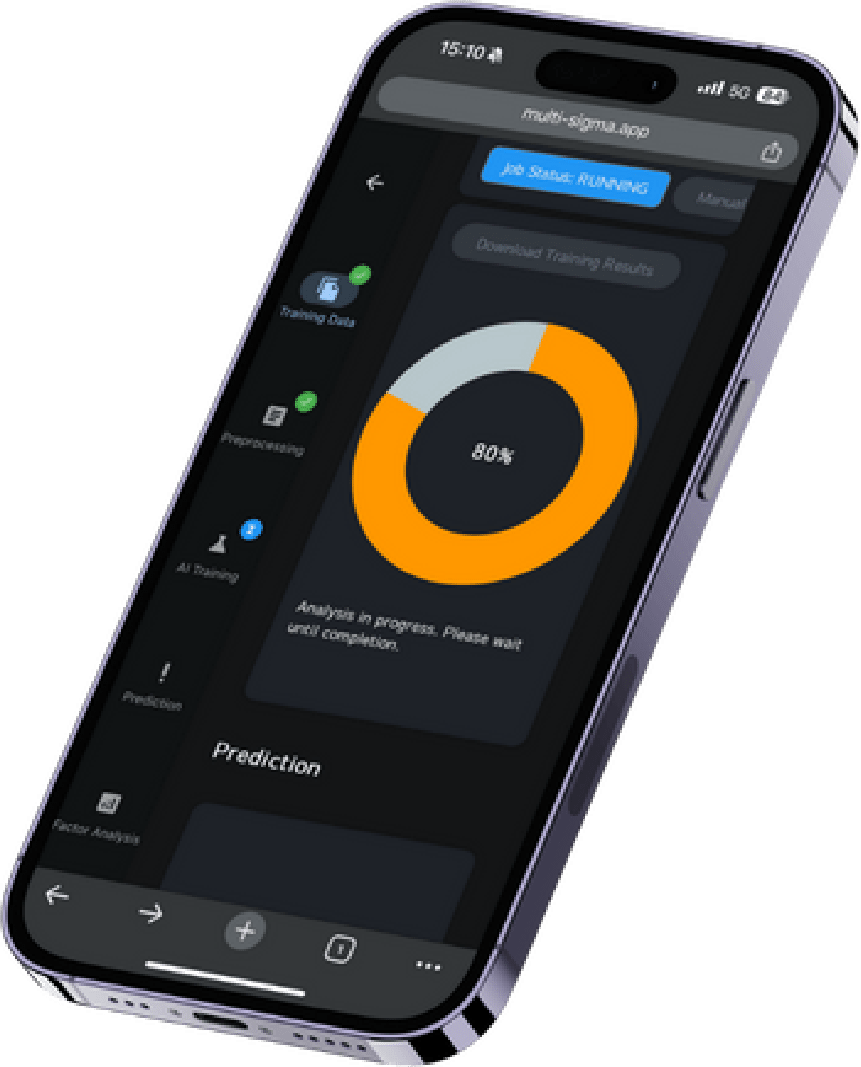

No-Code Interface and Cloud Accessibility

Multi-Sigma® is a no-code tool. Engineers operate it through a guided GUI. Because it runs in the cloud, no dedicated hardware is needed. Teams can start with a standard web browser.

Chain Analysis with Linked AI Models

Multiple surrogate models can be linked for system-level studies. For example, structure, fluid, and thermal models can be connected to explore trade-offs and reduce reworking. For assemblies such as a motor and a connected fan, linked models help derive solutions that optimize the combined system.

Integration with Control Simulations

Surrogate models created in Multi-Sigma® can be exported and used in external control-simulation tools. This connects component-level CAE results to system-level control design and supports validation across the full product.