Driving Innovation with AI Chain Analysis: Integrating Experimental Data for High-Performance MOF Development

Driving Innovation with AI Chain Analysis: Integrating Experimental Data for High-Performance MOF Development

Introduction: Revealing the Whole Picture Through AI Chain Models

Have you ever found yourself thinking, “I wish I could analyze data from different experiments together,” or “I want to combine multiple AI models to improve prediction or optimization”?

These are common challenges in R&D. Even with a deep understanding of individual systems or datasets, it is not always easy to grasp how they interact as part of a broader system.

This is where AI Chain Analysis comes in, a methodology that links separate experimental AI models in a stepwise sequence. By chaining together AI models and their respective inputs and outputs, it becomes possible to reveal causal relationships and latent patterns that would remain hidden in isolated analyses.

In this article, we present how the integration of AI models through AI Chain Analysis can create new value in research and development. Using Multi-Sigma, we demonstrate a case study in which this approach enabled a deeper understanding of the full process, from causal inputs through intermediate characteristics to final outcomes.

Specifically, we explore its application in the development of high-performance Metal-Organic Frameworks (MOFs). By applying AI Chain Analysis with Multi-Sigma, we achieved a significant breakthrough: the simultaneous optimization of CO₂ adsorption capacity and material density, which are two often conflicting goals in MOF synthesis.

The Role of MOFs in Achieving Carbon Neutrality

As climate change becomes an urgent global issue, technologies for capturing and storing CO₂ are gaining increased attention. MOFs are among the most promising materials in this field, and they are a class of porous crystalline materials.

MOFs consist of metal ions coordinated with organic linkers arranged in an orderly crystal structure. Thanks to their extraordinary surface area and finely tunable pore structures, MOFs hold immense potential in various applications including gas adsorption, separation, and catalysis.

In particular, MOFs are considered highly promising for CO₂ capture and separation, with the potential to surpass the performance of conventional materials. As such, they are increasingly recognized as a critical technology in the pursuit of carbon neutrality.

Unlocking the Power of Multi-Faceted Data in MOF Studies

In the field of MOF research, a wide variety of data is collected to serve different objectives. Each type of data carries unique value and contributes to distinct aspects of material development:

- Synthesis condition data: Information such as metal type, oxidation state, synthesis temperature, and time. This data is essential for establishing optimal synthesis protocols.

- Structural characteristic data: Properties like unit cell volume, specific surface area, and pore volume. These are fundamental to understanding the basic structure and physical behavior of MOFs.

- Functional characteristic data: Parameters such as density and gas adsorption capacity. These are used to evaluate and enhance the practical performance of MOFs.

Each of these data types plays an indispensable role within its own context. Synthesis condition data contributes to improving reproducibility, structural data deepens theoretical understanding, and functional data drives progress in practical applications. Collectively, they form the foundation for comprehensive and effective MOF development.

Transforming MOF Development through Integrated Experimental Data

In this study, we utilized the MOF synthesis prediction dataset from GitHub*¹ to demonstrate how integrating synthesis conditions, structural characteristics, and functional characteristics as three types of experimental data can lead to new insights in MOF development.

By combining these datasets, the following findings emerged:

- Clarifying chain effects: It was revealed that synthesis time influences CO₂ adsorption capacity through its effect on pore volume.

- Understanding trade-offs: The analysis identified structural factors that hinder the simultaneous optimization of density and adsorption performance.

- Discovering unexpected contributors: The +2 oxidation state emerged as a key stabilizing factor, consistently associated with favorable outcomes.

The Process of AI Chain Analysis

The AI Chain Analysis workflow using Multi-Sigma follows the steps below:

1. Data Integration:

Data from various sources is imported and preprocessed, including scaling and handling of missing values.

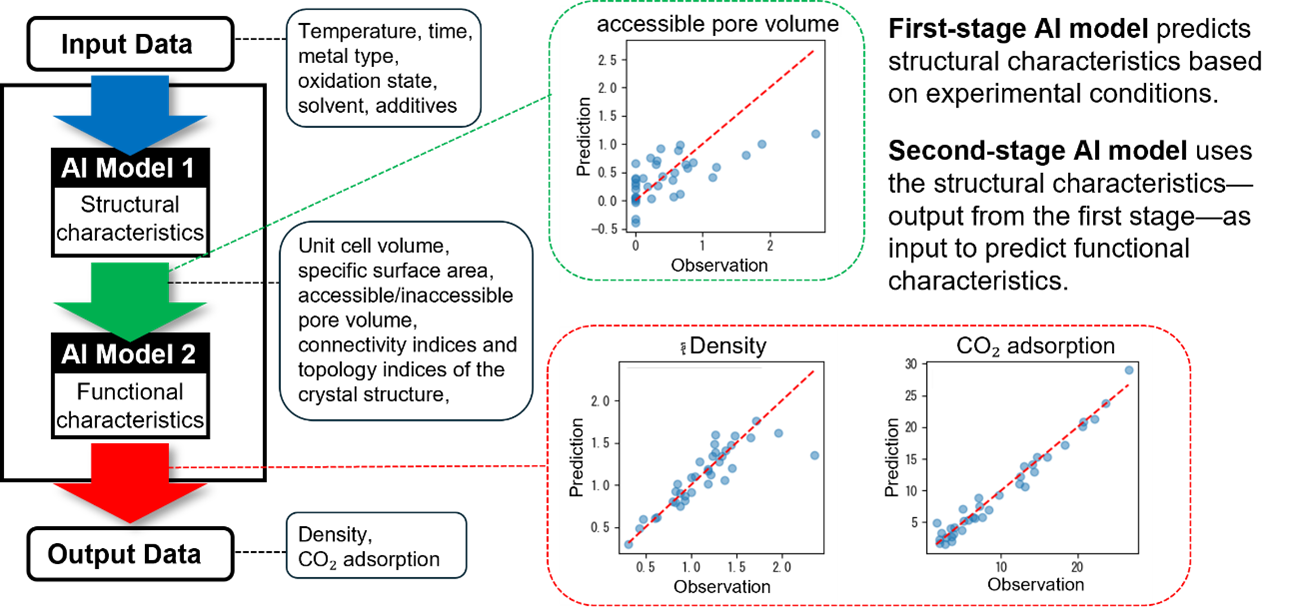

2. Chain Model Construction:

- AI Model 1: Predicts structural characteristics from synthesis conditions.

- AI Model 2: Predicts functional characteristics from the output of Model 1 (i.e., structural characteristics).

3. Model Linking:

The two models are linked together, enabling a seamless flow of analysis from synthesis conditions → structural characteristics → functional characteristics.

4. Contribution Analysis:

The impact of each factor is evaluated across the entire analytical chain to understand its influence.

5. Multi-Objective Optimization:

Using the complete chain model, Multi-Sigma searches for conditions that simultaneously optimize multiple target properties.

AI Chain Analysis with Multi-Sigma

In the AI Chain Analysis conducted using Multi-Sigma, a two-stage prediction model was constructed based on the following variables:

Input Variables (Synthesis Conditions):

- Metal types: Cd, Co, Cu, Dy, Eu, Fe, Gd, In, La, Mg, Mn, Ni, Tb, Y, Zn

- Oxidation states: +1, +2, +3

- Synthesis temperature (℃)

- Synthesis time (hours)

- Solvents 1, 2, 3: Various organic solvents

- Additives

Intermediate Variables (Structural Characteristics):

- Unit cell volume (ų)

- Specific surface area (m²/cm³)

- Accessible / inaccessible pore volume (cm³/g)

- Total surface area and total pore volume (volume-based)

- Connectivity and topology indices of the crystal structure

Output Variables (Functional Characteristics):

- Density (g/cm³)

- CO₂ adsorption capacity (measured at 298 K and 16 bar)

The AI Chain Model built using Multi-Sigma achieved the following prediction accuracy:

- Density prediction: R² = 0.730

- CO₂ adsorption prediction: R² = 0.970

Key Insights Revealed Through Factor Analysis

Factor analysis quantitatively identified the key variables influencing MOF performance:

Impact on CO₂ Adsorption Capacity

- Specific surface area and pore volume were found to be the most critical factors, accounting for approximately 80%.

- Crystal structure connectivity was the next most significant factor, contributing about 12%.

Impact on Density:

- Unit cell volume had the greatest influence, contributing roughly 51%.

- Crystal structure connectivity also played a major role, with an impact of approximately 32%.

Chain Effects from Synthesis Conditions

- Synthesis time had the highest impact, ranging from 17–20%.

- Synthesis temperature followed closely, with an influence of 16–19%.

- Oxidation state also had a non-negligible effect (9–12%), with a +2 oxidation state showing the most stable and favorable outcomes.

These findings provide highly actionable guidance for optimizing experimental design in MOF development. In particular, they quantitatively underscore the importance of precise control over synthesis time and temperature to achieve desired material properties.

Successful Design of an Optimal MOF

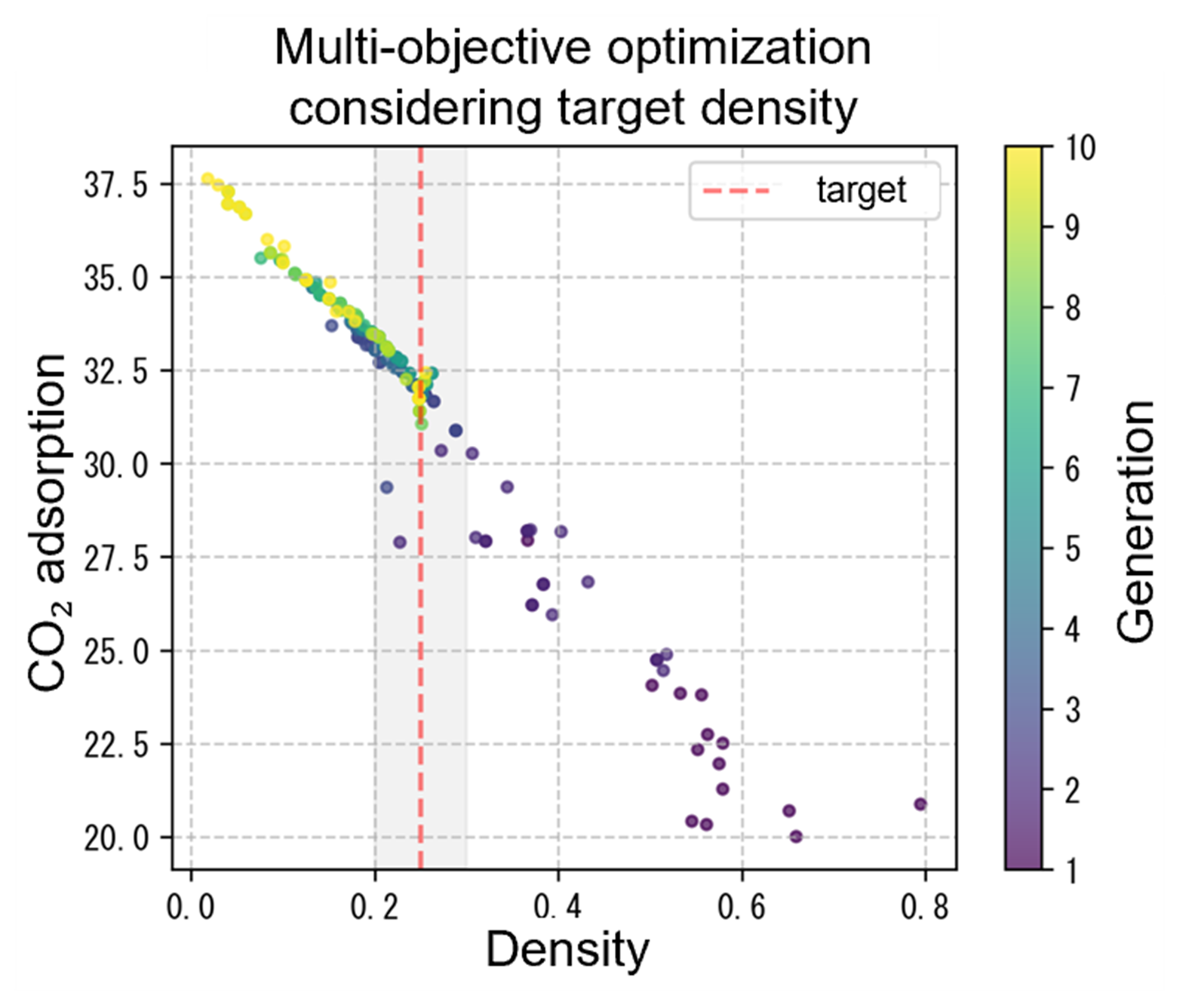

Using the chain model in combination with multi-objective optimization, we searched for synthesis conditions that would simultaneously satisfy two conflicting goals:

- Achieve a density close to 0.25 g/cm³ (a value suitable for industrial applications)

- Maximize CO₂ adsorption capacity

Through the optimization functionality of Multi-Sigma, the following synthesis conditions were identified:

- Synthesis temperature: 174℃

- Synthesis time: 408 hours

- Metal type: Indium (In)

- Oxidation state: +2

- Optimal combination of solvents and additives

Under these conditions, the resulting MOF was predicted to exhibit a density of 0.25 ± 0.005 g/cm³ and an excellent CO₂ adsorption capacity of 32.2, representing a well-balanced, high-performance material optimized for real-world applications.

Significance and Future Outlook of the Research

This AI Chain Analysis approach offers a transformative way to advance MOF development, with the following key benefits:

- Reduction in the number of experiments

- Shortening of development time

- Improvement in material performance

What stands out in particular is the value of the chain model incorporating intermediate variables (structural characteristics). This approach enables a deeper scientific understanding than traditional direct input-output prediction models. By tracing how specific synthesis conditions influence structural properties, which in turn determine functional performance, the underlying causal mechanisms become visible.

This not only provides essential scientific insight into why certain synthesis conditions lead to specific outcomes, but also enhances prediction accuracy by including the intermediate step.

By leveraging AI Chain Analysis, previously hidden causal relationships can be uncovered, streamlining the entire development cycle. The sequential understanding of synthesis conditions → structural characteristics → functional characteristics significantly reduces trial-and-error efforts and empowers researchers to design more precise and efficient experiments.

Expanding the Application of Data Integration Across Disciplines

By leveraging AI chain analysis, researchers can uncover previously hidden causal relationships and streamline the entire development cycle. In particular, the sequential understanding of synthesis conditions → structural characteristics → functional characteristics helps reduce trial-and-error and enables more appropriate experimental design.

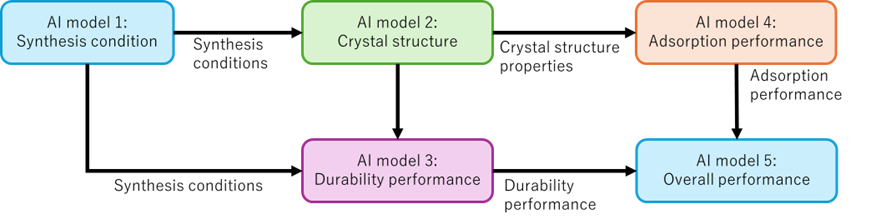

With Multi-Sigma, even more complex forms of AI Chain Analysis can be conducted. In this case, two models were connected in series, but the platform supports flexible modeling approaches, such as the integration of three or more models or even branched structures with multiple pathways, to reflect the causal structure of the specific research domain. This flexibility opens the door to applying chain modeling in projects involving complex phenomena or multi-stage processes.

Importantly, this approach is not limited to MOF development. AI Chain Analysis using Multi-Sigma is applicable across a wide range of research and development domains, such as:

- Pharmaceutical development: Analyzing the chain of compound structure → pharmacokinetics → therapeutic effects

- Agricultural science: Analyzing the linkage of cultivation conditions → plant physiology → yield and quality

- Manufacturing processes: Understanding the links between material properties → process characteristics → product quality

Unlocking the Future of Innovation through AI Chain Analysis

With Multi-Sigma, data integration and AI Chain Analysis can now be executed through intuitive GUI operations. This shift signals the arrival of an era in which researchers and domain experts can fully harness the power of data, even without specialized knowledge in data science.

Across diverse fields such as pharmaceuticals, agriculture, manufacturing, and environmental science, AI Chain Analysis is expected to drive new discoveries, streamline workflows, and accelerate innovation.

As this analytical approach becomes more widespread, it holds great promise for transforming research and development across disciplines. It can contribute to solving critical global challenges, including carbon neutrality, sustainable food production, advanced healthcare, and resource circularity.

By unraveling complex causal relationships through a process-oriented mindset, we unlock the potential for breakthrough solutions to the pressing problems facing humanity today.

*1:GitHub (https://github.com/aimat-lab/MOF_Synthesis_Prediction)

機械学習を使った分析や予測が日常的に行われる今、協調フレームとしてのMulti-Sigma®の役割は増すばかりです。

『どのような場面で活用できるのか』をもっと知りたい方や、実際の利用シーンを見てみたい方は、是非一度お気軽にご相談ください。

In a world where machine learning-based analysis and prediction are becoming everyday practices, the role of Multi-Sigma® as a collaborative framework is more crucial than ever.

If you're interested in learning more about how it can be applied or want to see real-world examples, feel free to contact us.