【Overview】

AIZOTH Inc. (hereinafter referred to as “AIZOTH”) has been entrusted with the NEDO project “Development of High-Efficiency Refrigeration and Air Conditioning Technology for Practical Application of Next-Generation Low GWP Refrigerants,” in collaboration with Kyushu University, Kyushu Sangyo University, and the National Institute of Advanced Industrial Science and Technology.

The objective of this project is to develop high-efficiency refrigeration and air conditioning technology using next-generation low GWP (Global Warming Potential) refrigerants suitable for various equipment, including household air conditioning units. Specifically, the research involves the selection of HFO blend refrigerants, development of key components such as heat exchangers and compressors, and the creation of evaluation models for the safety and environmental impact of refrigerants. By achieving performance equal to or surpassing existing fluorocarbon products, the project aims to accelerate the societal implementation of environmentally friendly refrigeration and air conditioning technology, reconciling both greenhouse gas reduction and ozone layer protection. The project commenced in 2023 with the goal of contributing to a sustainable and eco-friendly refrigeration and air conditioning landscape.

【Background of Project Initiation】

The refrigerants used in refrigeration and air conditioning equipment have transitioned from ozone-depleting CFCs and HCFCs to HFCs, known as alternative refrigerants. However, these alternative refrigerants pose a problem due to their high global warming potential (GWP). Considering the increase in emissions accompanying the widespread adoption of alternative refrigerants and the subsequent strengthening of international regulations, particularly through the Kigali Amendment to the Montreal Protocol in 2016, there has been a gradual reduction obligation for the production and consumption of alternative refrigerants. Advanced countries are now required to achieve an 85% reduction from the baseline year by 2036. Additionally, aiming for carbon neutrality by 2050, there is a global call to essentially eliminate emissions. Controlling the emissions of alternative refrigerants, which show an increasing trend among greenhouse gases, is an urgent challenge. The development of next-generation refrigerants and equipment as alternatives to alternative refrigerants, and their societal implementation, is of immediate importance.

On the other hand, many next-generation refrigerant candidates with minimal impact on global warming face technical challenges to achieve performance equal to or surpassing traditional HFC refrigerants. Moreover, there are safety concerns such as flammability and chemical instability. As a result, globally, the practical application of refrigeration and air conditioning equipment using next-generation refrigerants has not been realized. One significant factor contributing to this is the lack of established standardized evaluation methods for the basic characteristics and safety of next-generation refrigerants. Furthermore, in the field of refrigeration and air conditioning equipment, despite the application of next-generation refrigerants in some areas, there are widespread technical challenges, hindering broad adoption.

In this project, we target household air conditioning units and similar equipment not currently utilizing next-generation refrigerants as alternatives to existing fluorocarbons. We will conduct a comprehensive process from screening new blended refrigerants to the development and evaluation of applicable technologies, establishing foundational technologies to guide the design of applicable equipment. Additionally, by focusing on the development of essential and peripheral components necessary for the widespread adoption of next-generation low GWP refrigerants in household and commercial air conditioning units, as well as commercial refrigeration and freezing equipment, we aim to stimulate private enterprises to expedite the early development and market launch of next-generation low GWP refrigerants and their applicable equipment.

【Research and Development Contents】

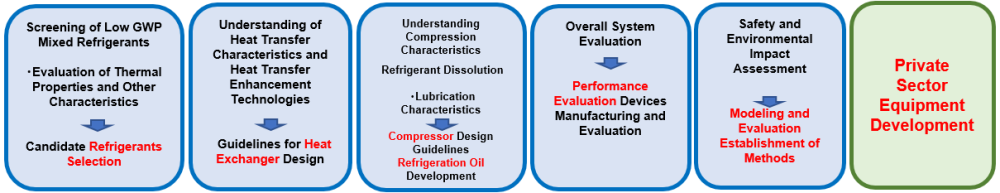

This project primarily consists of two research and development components. The first research and development item is “Development and evaluation of low GWP mixed refrigerants suitable for home air conditioning.” Building on insights gained from previous related research and development projects on blended refrigerants, we will conduct an early screening of HFO blend refrigerant candidates that can be implemented in household air conditioning units. Additionally, we will develop foundational technologies such as design guidelines for key components like heat exchangers and compressors that can accommodate the selected HFO blend refrigerant. Furthermore, we will work on the development of models and evaluation methods for assessing the safety of refrigerants and the environmental impact of corresponding equipment.

The second research and development item is “Development of equipment compatible with low-GWP refrigerants (residential/commercial air conditioners, refrigerated/freezer showcases, and others).” Leveraging the outcomes of previous related research and development projects and expanding on the knowledge of refrigerant and air conditioning element technologies for household air conditioning units within this project, we aim to develop equipment and peripheral devices that achieve performance equal to or surpassing currently available fluorocarbon products while being compatible with next-generation low GWP refrigerants.

In this project, AIZOTH will utilize AI-based analytical tools to enhance the efficiency of research and development. Specifically, for low GWP blended refrigerant-compatible air conditioning equipment, AIZOTH will contribute to the development of the Life Cycle Climate Performance (LCCP) evaluation method, data management related to appliance demand, consideration of future demand estimation methods, implementation of Life Cycle Assessment (LCA) evaluations, refinement of environmental impact estimations for low GWP blended refrigerant-compatible equipment, and the exploration of measures for reduction.

Please refer the link