AIZOTH Inc. was selected by NEDO with the project name, 「Development of aluminum resource upgrade recycling system technology toward a circular economy」 on July 2nd, 2021, in the public offering for 「Recycling Technology of Aluminum Resource for the Resource Circular Society」 by New Energy and Industrial Technology Development Organization (NEDO). This period of this project starts from 2021 and end at 2025 (plan).

Project name

Development of aluminum resource upgrade recycling system technology toward a circular economy

Contents

Recycling Technology of Aluminum Resource for the Resource Circular Society

Aluminium has the following properties and is getting high attention for lightweighting transportation equipment such as automobiles.

- Light weight

- Rust resistant

- Easy to process

- High thermal conductivity

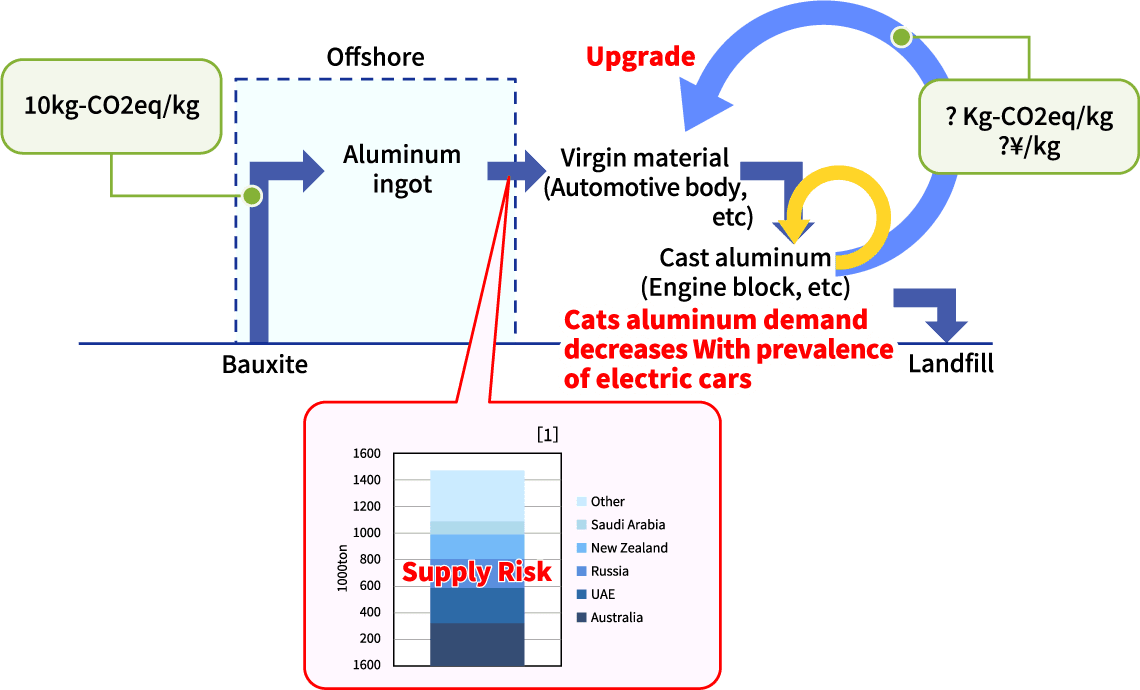

Currently, aluminum is imported as ingot after raw materials such as bauxite are processed by electrical refining in foreign countries. Aluminium processed from high purity raw material is used as high purity wrought aluminum for applications such as automobile body.

When wrought aluminum is recycled, impurity concentration increases. As a result, recycled wrought aluminum is no longer used for wrought aluminum applications and is down recycled to cast aluminum, which is used for example for engine blocks. This recycling system is called cascade recycling. Cascade recycling downgrades aluminum quality as its impurity concentration increases over recycling.

Thus, applications for recycled aluminum have to be chosen based on the given aluminum quality. After some round of recycling, recycled aluminum is landfilled. Although a portion of wrought aluminum is recycled, the majority of high purity wrought aluminum is imported.

There three issues in the above system.

- Approximately 10 kg of greenhouse gas is emitted in order to produce 1 kg of aluminum ingot through an electrical refine processing from bauxite offshore.

※Approximately 3 kg of GHG is emitted to produce steel and plastic. Compared with those, the amount of GHG of aluminum production is high. - In the future, with prevalence of electric cars, the demand for engine blocks disappears. This will eliminate the destination for recycled cast aluminum.

- There is a risk in supply and cost since we rely 100% on the import for aluminum ingot.

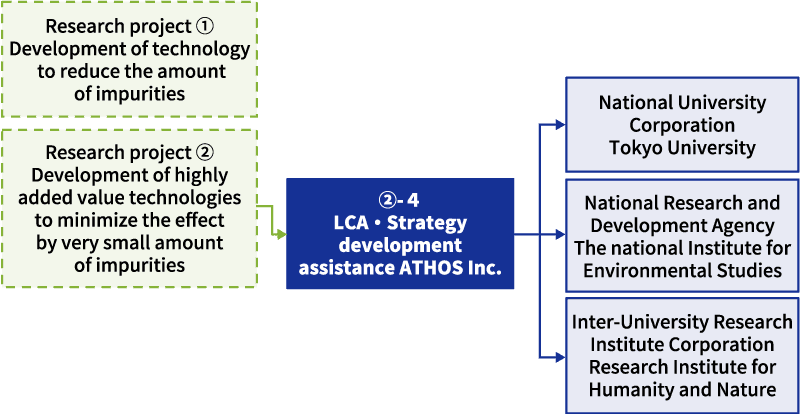

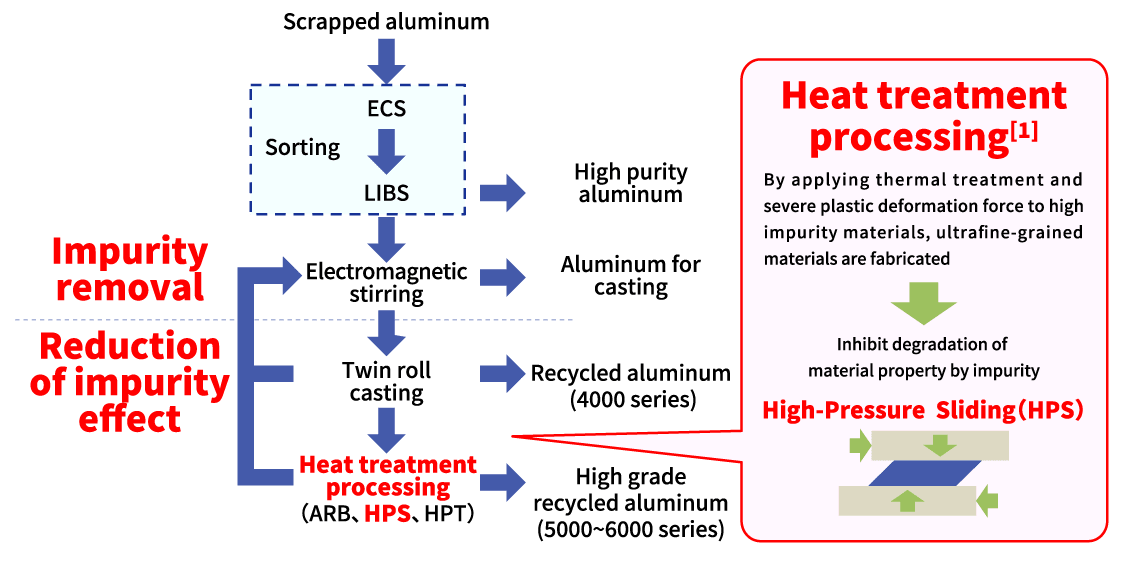

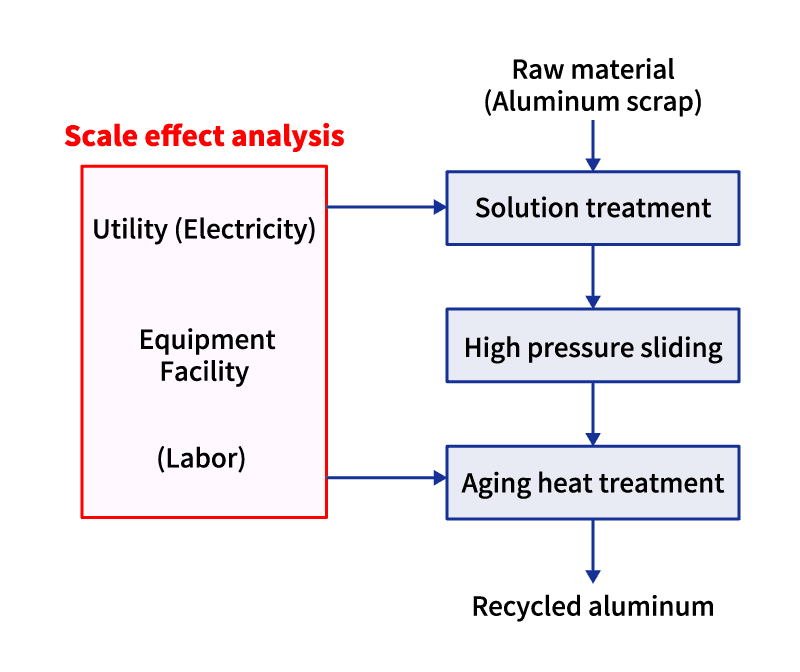

In this project, we develop the upgrade recycling technology from high impurity aluminum to the one with the same features of high purity aluminum. Here, AITHOS Inc. performs cost・environmental impact analysis for the upgrade recycling technology. In addition, AITHOS Inc. does a research and development work to find the optimized conditions in each recycle processes.

Aluminum upgrading recycle system

Objective, Scope, Functional unit, System boundary

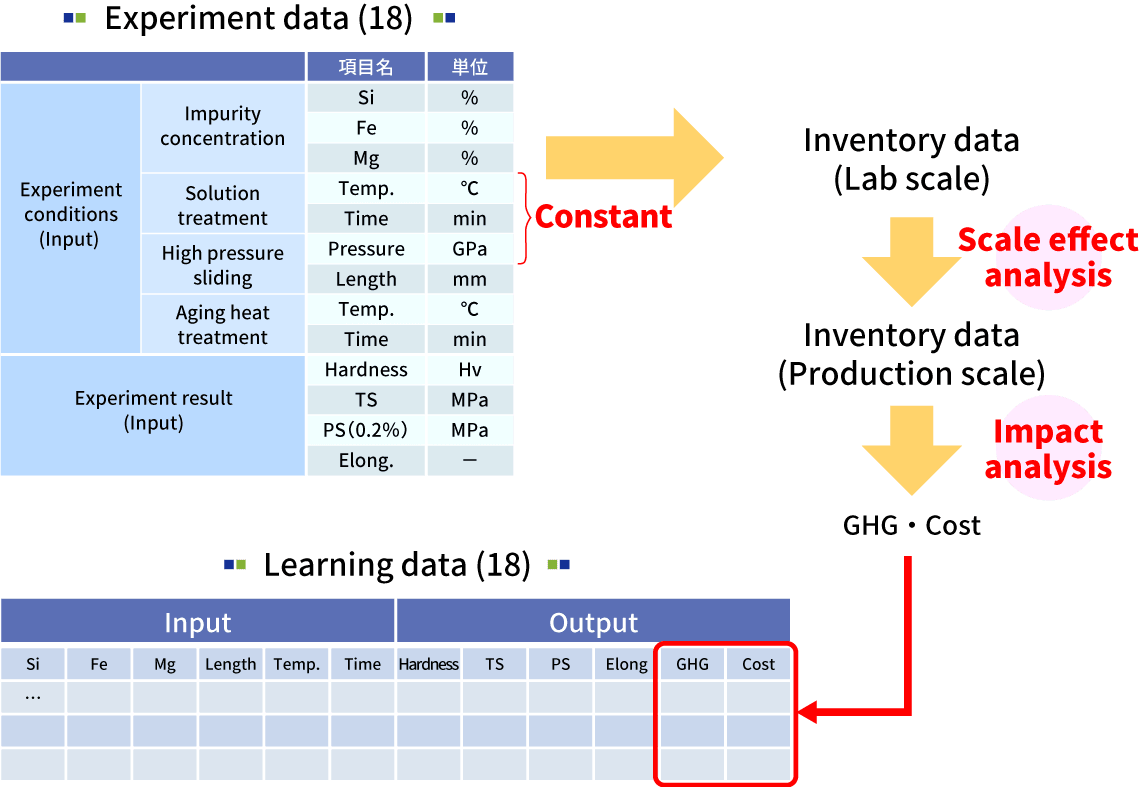

Inventory Analysis (Creation of learning data)

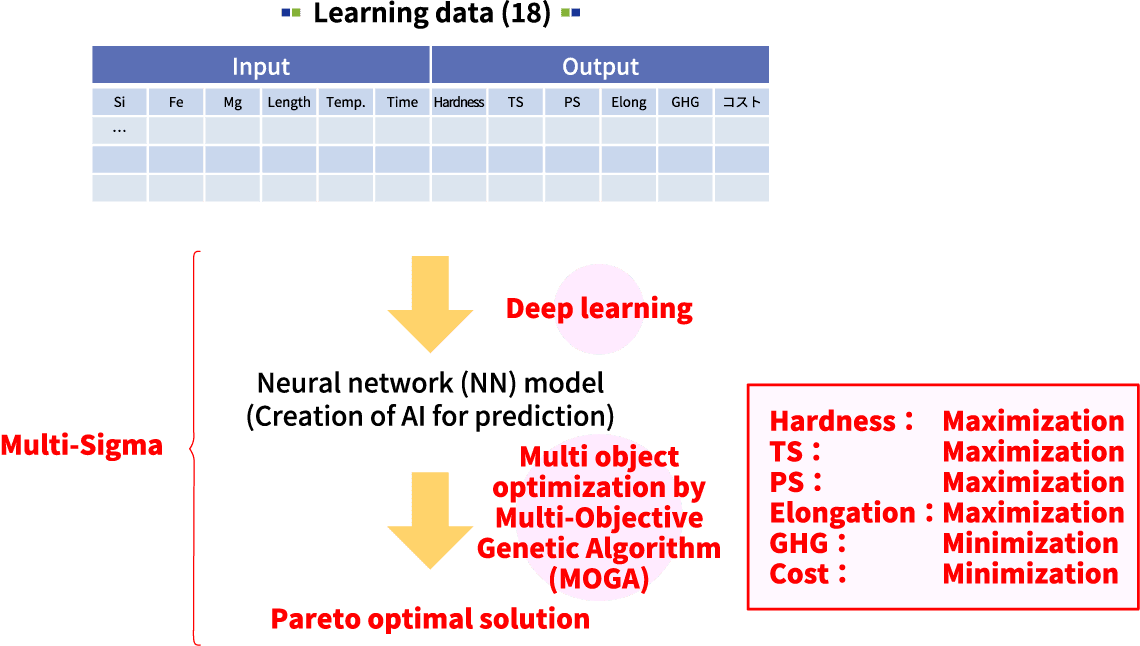

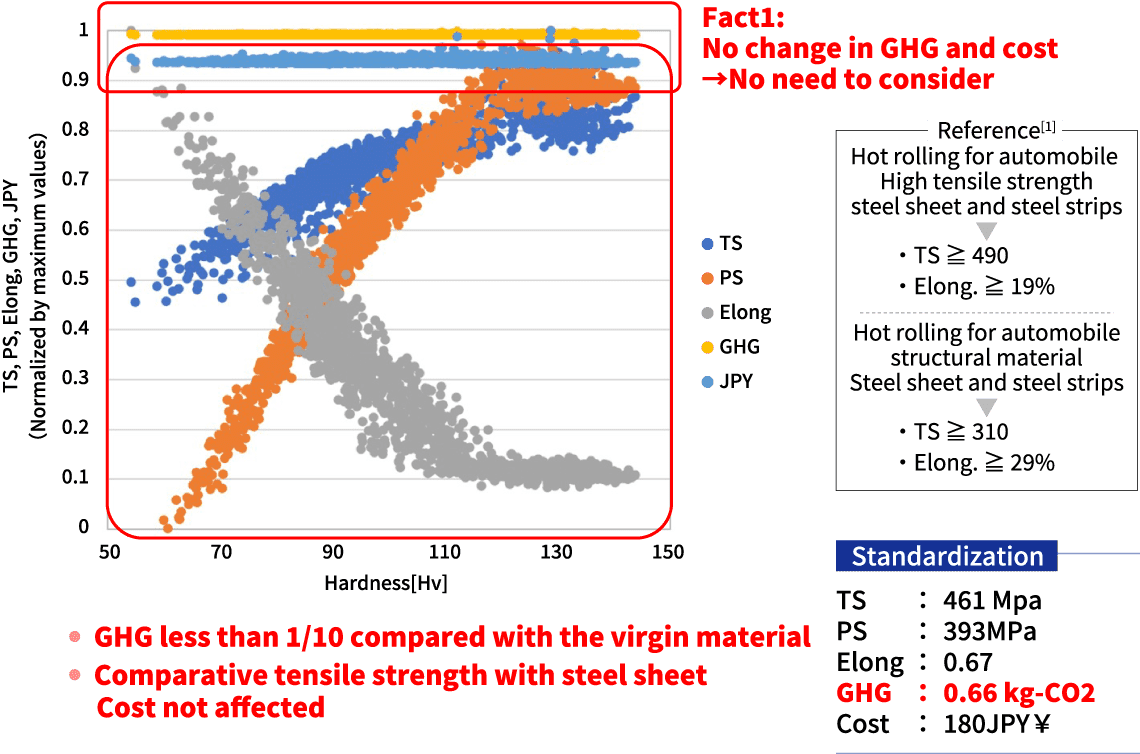

AI analysis

Results

Please see the following link for the subject below.

About a decision for the organization of 「Recycling Technology of Aluminum Resource for the Resource Circular Society」 project

https://www.nedo.go.jp/koubo/EV3_100226.html

Introduction: 「Recycling Technology of Aluminum Resource for the Resource Circular Society」 project

https://www.nedo.go.jp/activities/ZZJP_100195.html

Acknowledgement

This achievement was made possible by the subsidy of New Energy and Industrial Technology Development Organization (NEDO) project (JPNP2100).