This case study developed a high-accuracy AI surrogate model from injection-molding simulation results for PET containers and successfully identified robust optimal solutions while accounting for noise factors.

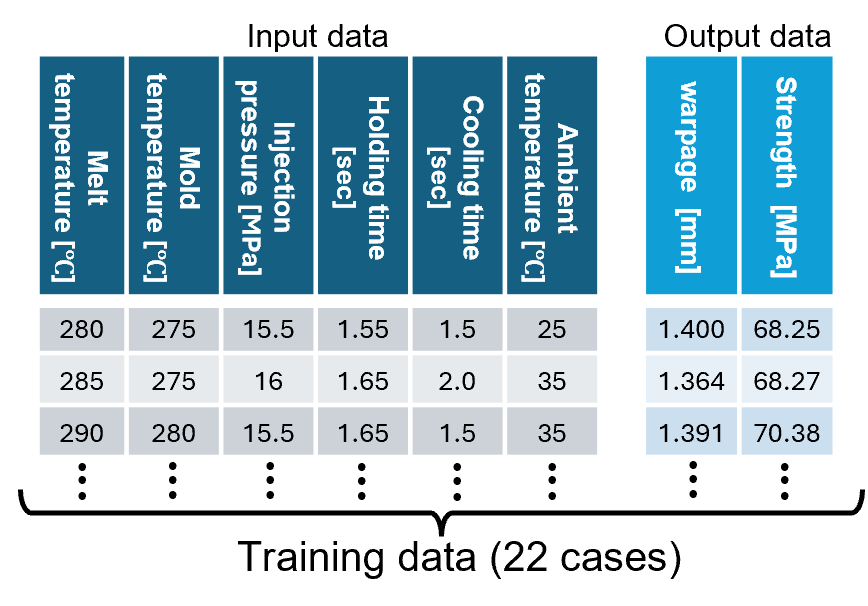

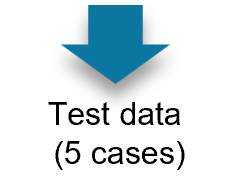

1. Building a Surrogate Model with Multi-Sigma®

Using Multi-Sigma®, this case study developed a high-accuracy surrogate model from PET injection-molding simulations and identified noise-robust optimal molding conditions.

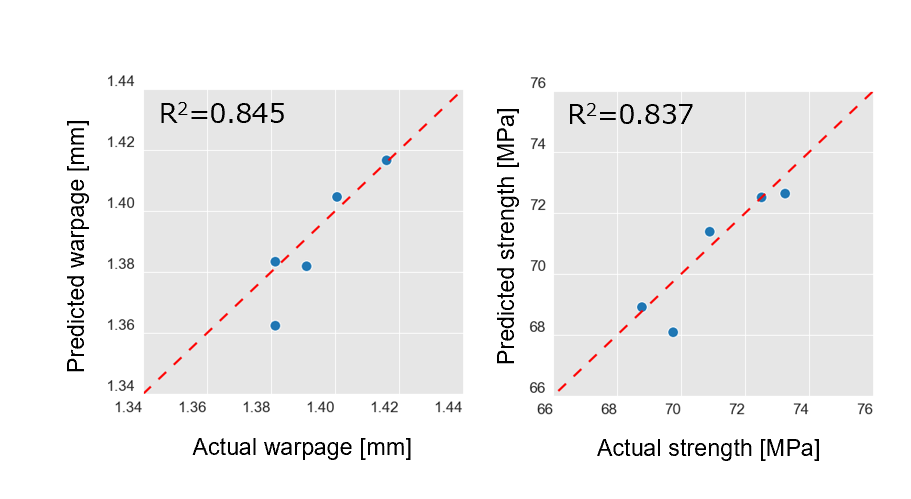

2. Contribution Analysis of Molding Conditions Using Multi-Sigma®

Using the contribution-analysis feature, we quantitatively evaluated how each molding condition impacts warpage and strength, yielding the following findings:

Notably, melt temperature emerged as the primary factor mediating the trade-off between these two properties, providing important insights for balanced design of molding conditions.

3. Exploration of Robust Optimal Solutions Using Multi-Sigma®

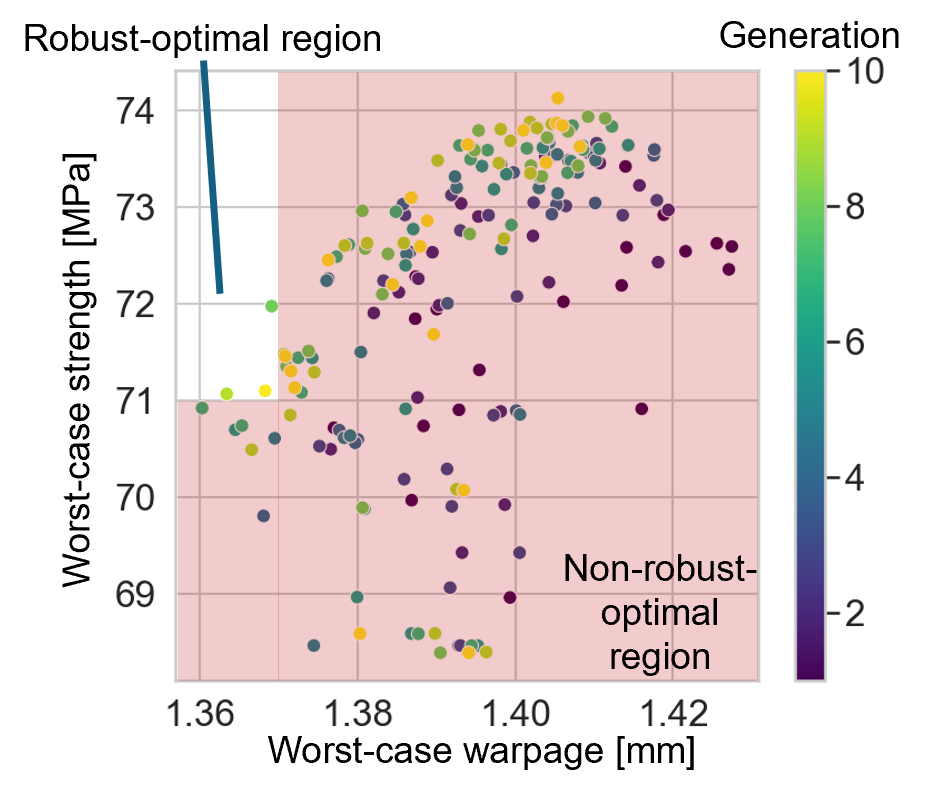

Multi-Sigma® supports robust optimization by explicitly accounting for noise-factor variability. In this case study, because ambient temperature is hard to control, we model it as a noise factor, sweep 25–35 °C, and identify settings that satisfy the following performance criteria:

Worst-case warpage ≤ 1.37 [mm]

Worst-case strength ≥ 71 [MPa]

These robust optimal molding conditions were derived by rapidly evaluating large numbers of scenarios using the Multi-Sigma® surrogate model.

Note 1: Note: The data used in this analysis is processed and edited based on the data published in the article below, under Creative Commons Attribution 4.0 International (CC BY 4.0) license.

Data source: Chen et al. (2023), Processes, 11:414. https://doi.org/10.3390/pr11020414

Note 2: The strength data are synthetic, modeled on real world data.