This case study showcases how Multi-Sigma’s AI-driven analysis platform optimizes the aluminum recycling upgrade process by enhancing mechanical properties while minimizing greenhouse gas (GHG) emissions and costs. This project was conducted as a part of a NEDO-funded project, this study leverages AI to drive significant advancements in sustainability and performance.

1. AI analysis

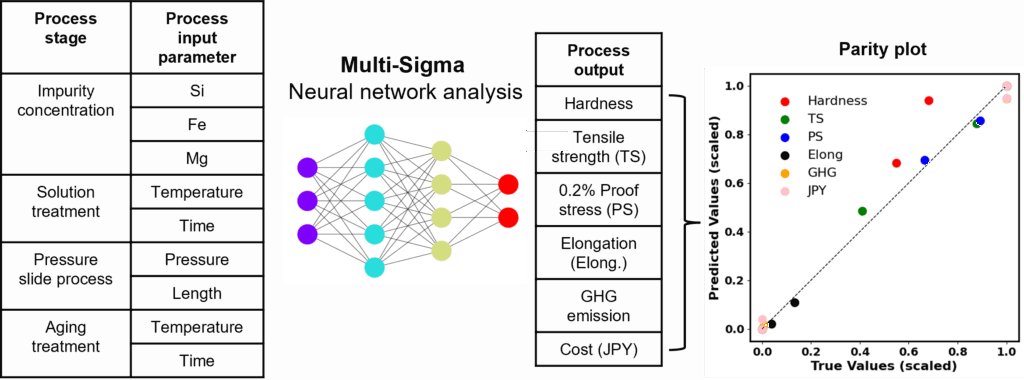

A dataset containing 18 process samples was analyzed. The AI model was trained using key input parameters from the aluminum recycling process, including impurity concentration, solution treatment duration, high-pressure sliding process, and aging treatment conditions. The output parameters included the mechanical properties of the recycled aluminum, as well as associated GHG emissions and cost estimates.

2. Factor Analysis

The factor analysis identified the most influential parameters affecting the aluminum recycling process:

- Length of the high-pressure sliding process (~ 41% influence).

- impurity concentration (~ 19% influence).

- solution treatment time (~ 12% influence).

3. Multi-objective Optimization of the Recycle Process

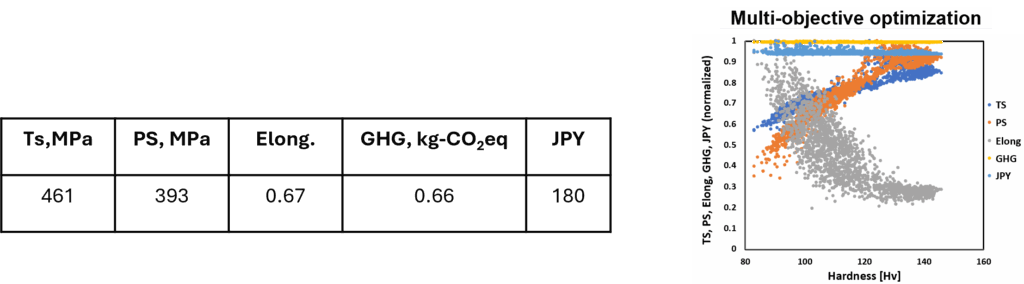

Multi-Sigma’s optimization module was utilized to determine the ideal recycling process parameters. The objective was to maximize key mechanical properties—such as tensile strength, 0.2% proof stress, and elongation—while minimizing GHG emissions and cost.

Source: NEDO project (Development of advanced circulation technology for aluminum materials)

https://www.nedo.go.jp/english/activities/activities_ZZJP_100195.html

https://aizoth.com/research-project/nedo/