Design Optimization of an Extracorporeal Centrifugal Blood Pump Using Multi-Sigma®

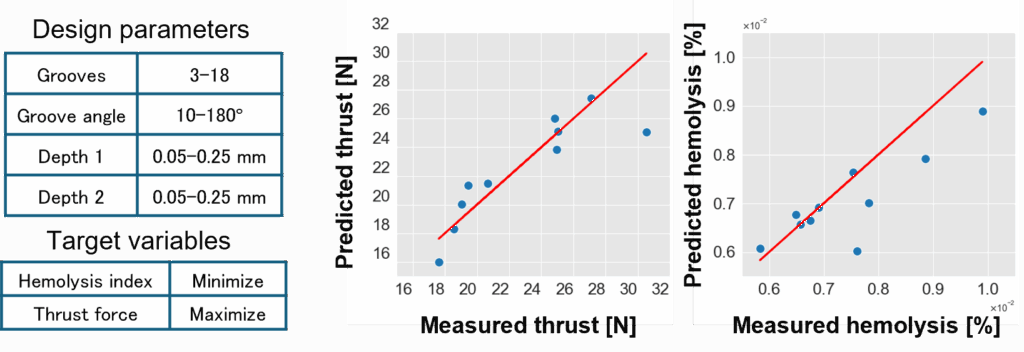

The dynamic pressure bearing in this pump involves multiple design parameters. Adjusting these parameters impacts two key performance metrics: (1) thrust force generated by the bearing, (2) hemolysis index (red blood cell damage). In this project, a surrogate model was built using Multi-Sigma®, based on simulation data from 3D CAD and Computational Fluid Dynamics (CFD). This model enables efficient prediction, sensitivity analysis, and multi-objective optimization.

1. Thrust force and Hemolysis index Prediction Using Multi-Sigma®

Using Multi-Sigma®, a surrogate model was built from approximately 50 simulation results.

The model demonstrated high prediction accuracy, with correlation coefficients of 0.8733 for thrust force and 0.8547 for the hemolysis index.

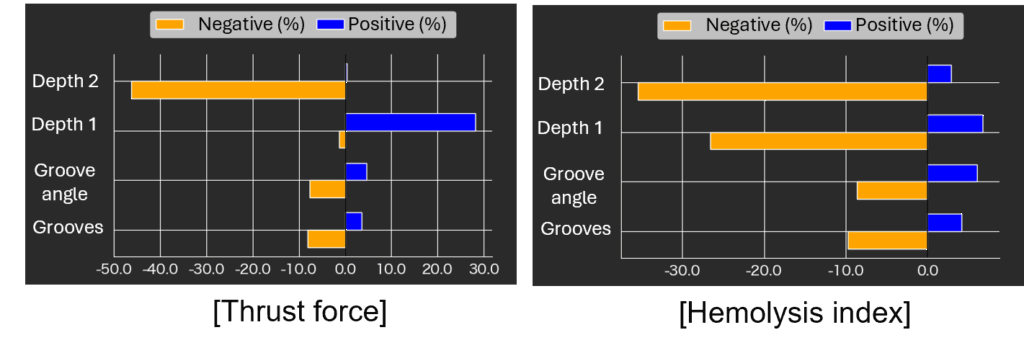

2. Factor Analysis of Thrust Force and Hemolysis Index Using Multi-Sigma®

Factor analysis based on sensitivity analysis was conducted using Multi-Sigma®. The results revealed that groove depth has a significant impact on both thrust force and the hemolysis index. Furthermore, it was found that the inlet (depth 1) and outlet groove depths (depth 2) have opposing effects on the thrust force.

3. Optimization of Thrust Force and Hemolysis Index Using Multi-Sigma®

Using the surrogate model built with Multi-Sigma®, a Pareto curve was successfully generated by applying a multi-objective genetic algorithm to simultaneously maximize thrust force and minimize the hemolysis index. By selecting design parameter values corresponding to desirable solutions on the Pareto curve (in this case, points located toward the lower right), it becomes possible to develop a high-performance artificial heart.

![Optimization of Thrust Force and Hemolysis Index Using Multi-Sigma®

Hemolysis index [%]

Thrust force [N]](https://aizoth.com/wp-content/uploads/2025/07/E015_4.png)

By using Multi-Sigma® to build a surrogate model, we found the optimal solution with just 50 simulations, instead of the 7,200 originally needed—achieving over 99% efficiency in simulation workload. While groove count was previously thought to be the key factor for thrust force and hemolysis index, factor analysis revealed that groove depth plays more critical role.

Note: “Pioneering the Future with Technology – Innovative Design of Experiments and R&D Efficiency through AI”, Nikkan Kogyo Shimbun, February 18, 2021

This case study was recalculated using data from the example featured in the above article.

https://aizoth.com/2021/03/nks210218/

https://www.aist.go.jp/aist_j/new_research/2020/nr20201013/nr20201013.html